FENDER-EDGE

Marine Fender Defense System

The Last Safety Barrier Between Vessels and Value

Happy New Year 2026!

FENDER-EDGE news. A New Year of Harmony & Partnership! Dear Valued Partner, As we step into 2026, all of us at FENDER-EDGE extend our warmest

FENDER-EDGE Authorized “A To Z Marine & Offshore Services WLL”as Sales and Service Provider in the GCC region.

FENDER-EDGE news. FENDER-EDGE Authorized “A To Z Marine & Offshore Services WLL”as Sales and Service Provider in the GCC region. We are excited to officially

Merry Christmas 2025

FENDER-EDGE news. MERRY CHRISTMAS 2025 Dear Partners, Regardless of the stage our cooperation has reached, first and foremost, FENDER-EDGE would like to express our sincerest

FENDER-EDGE Pneumatic Fender White Paper Published in 2025.

FENDER-EDGE news. FENDER-EDGE Pneumatic Fender White Paper Published in 2025. This White Paper delivers a technical analysis of FENDER-EDGE PneumaCell™ (pneumatic fender) superiority across three

PneumaCell™

ISO 17357-1:2014 just serves as the foundational standard, with its key superiority being the ability to maintain optimal performance especially in various harsh environments.

CushionCell™

Variety of manufacturing method are available to meet different berthing requirements. Low hull pressure, Non-marking, No burst risk, Unsinkable, Anti-UV no discoloration.

Rubber Fender

Rubber fender offer several advantages, including durability, resistance to harsh environmental condition and effective energy absorption to protect vessel during berthing.

ShipGuard™

Safe performance of ship launching airbag is the first priority, nothing else. So all its advantages come only from how to ensure safety. 4.5 times safety factor far ahead in the industry.

FENDER-EDGE

about us

EDGE MARITIME (QINGDAO) TECHNOLOGY CO.,LTD. provide maritime, infrastructure and specialized equipment manufacturing and supply chain solutions, with “FENDER-EDGE” as “EDGE MARITIME TECHNOLOGY” premier brand dedicated to marine fender defense system.

FENDER-EDGE

Manufacturing

FENDER-EDGE builds safe and reliable fender systems. We focus on manufacturing all major components in-house at our own facilities. This ensures the highest quality and reliability…

FENDER-EDGE

DESIGNING

The designing provided by FENDER-EDGE come from fender raw materials, fender selection and layout, special purpose fender design and customization…

FENDER-EDGE

Testing

Testing is conducted according to “Testing Standard” and “Testing Equipment”. Our laboratory tests every batch of rubber and key materials to ensure compliance with material requirements for each order…

FENDER-EDGE

INNOVATING

We possess a highly experienced technical team. Their extensive on-site experience has given them a deep understanding of the “Weakness” in fenders. They continuously strengthen these “Weakness” through: Fender Structural Design, Rubber Compounding Process, Testing Methods, Production Processes etc…

FENDER-EDGE

after sale service

FENDER-EDGE stand firmly behind the high quality and durability of marine fender defense system. To ensure customer complete peace of mind, we provide all-range products 24 months warranty…

FENDER-EDGE

TECHNICAL SUPPORTING

FENDER-EDGE attaches great importance to technical and innovative development. This expert knowledge is available to you at every stage, from design and manufacturing to testing and on-site installation, providing sufficient technical support at every stage of the order…

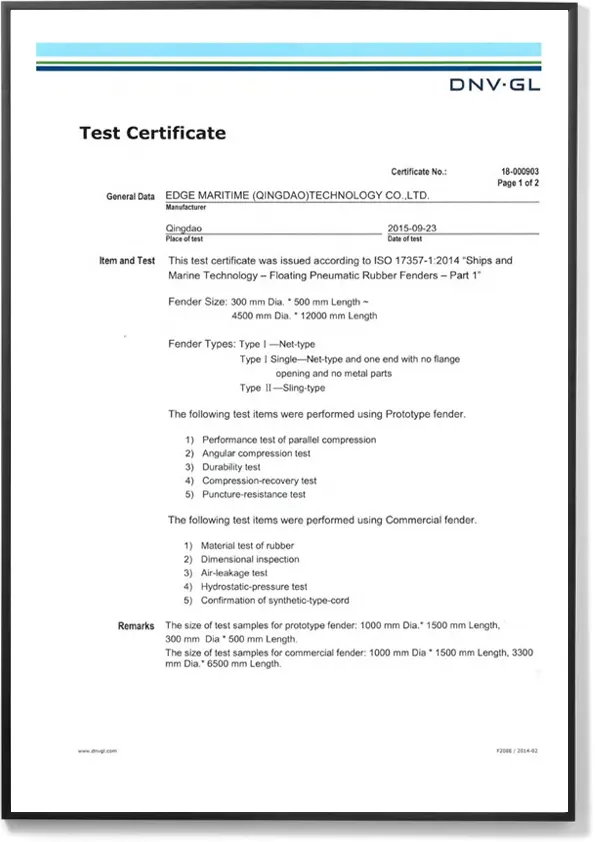

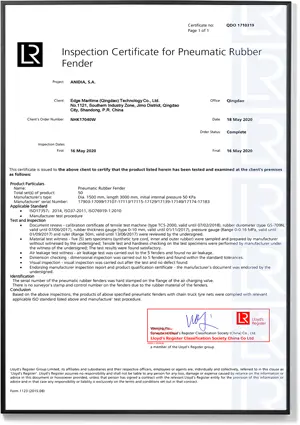

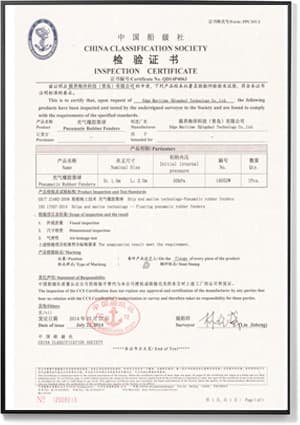

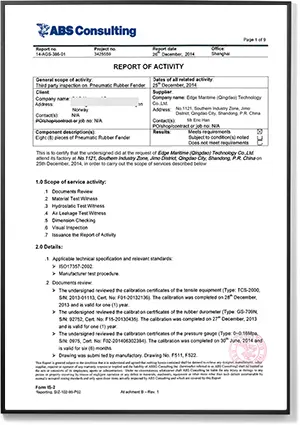

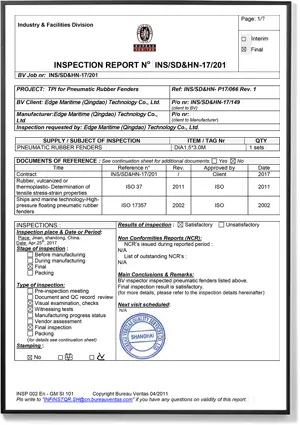

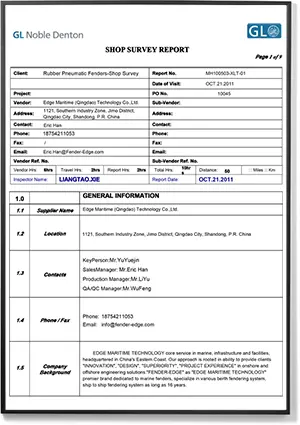

QUALIFICATIONS

FENDER-EDGE

FENDER-EDGE

CONTACT US

Your Message Will Be Replied Within 1 Hour.

Manufacturing Center

Southern Industry Zone, Jimo District,

Qingdao City, Shandong,

P.R. China

+ 86 185-6012-2692

+ 86 185-6012-2692